Embracing Automation in Cannabis Packaging

Introduction

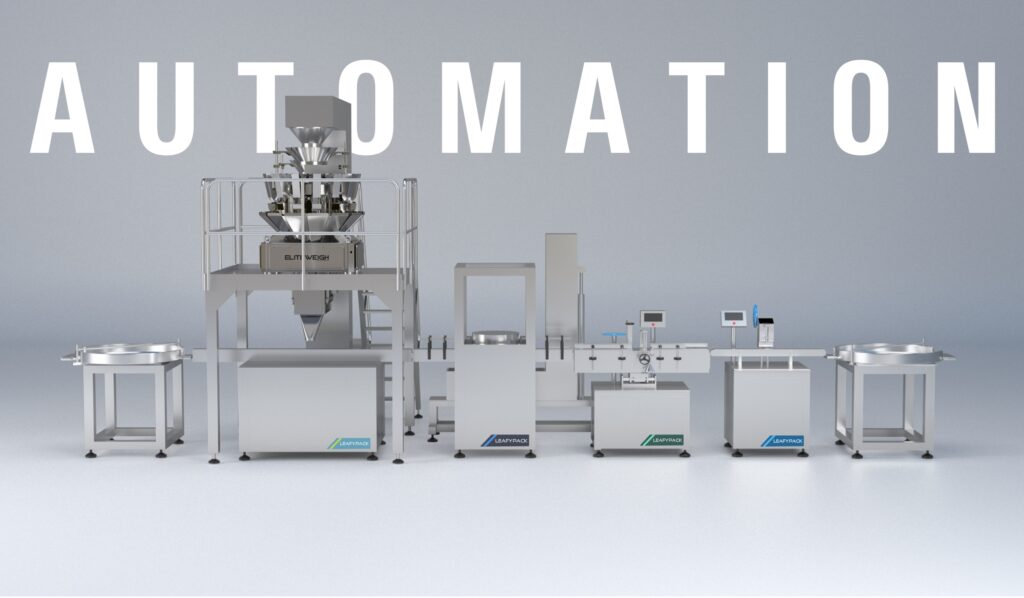

The cannabis packaging industry is continually evolving, and automation has become a driving force for innovation. By implementing automated packaging processes, businesses can significantly improve efficiency, reduce labor costs, and maintain product consistency. This article will provide an overview of various automated packaging processes and their benefits in the cannabis industry.

Types of Automation

Filling Solutions

Automated filling solutions, such as liquid concentrate filling, ensure precise and consistent product dosing. By using advanced machinery like the Atomic C-Cell Cartridge Filling and Capping Machine, businesses can streamline their production process, reduce human error, and increase output.

Capping Solutions

Automated capping solutions, like those offered by capping machines, are essential for maintaining product freshness and ensuring tamper resistance. The Automatic Capping Machine with Lid Feeder is an example of advanced equipment that can secure products and create a polished, professional appearance that appeals to customers.

Labeling Solutions

Automated labeling solutions, such as the Pre-Roll Tube Label Machine and the Round Container Wrap Labeler, help ensure that every product has accurate, professional-looking labels. By automating the labeling process, businesses can maintain brand consistency and comply with regulations while speeding up production.

Bagging Solutions

Automated bagging solutions, like the EcoBagger and Pack 520 Horizontal Flow Pack Machine, enable businesses to create custom bags for their products quickly and efficiently. By automating this process, businesses can optimize their packaging workflow and maintain a consistent, professional appearance.

Benefits of Automation

Increased Production Speed

Automated packaging processes significantly speed up production, allowing businesses to meet growing demand and stay competitive in the cannabis industry. Machines like the Apollo Pro Pre Roller and the RotoBagger help businesses increase their output without sacrificing quality or consistency.

Reduced Human Error

Automation reduces the potential for human error, ensuring that every product meets the company’s high standards. By utilizing advanced machinery, businesses can maintain product quality and prevent costly mistakes that could harm their reputation or result in regulatory fines.

Improved Product Quality

Automated packaging processes maintain a consistent level of quality across all products, ensuring that customers receive the same great experience every time. By employing automation, businesses can maintain a high level of quality control and instill confidence in their customers.

Conclusion

Embracing automation in the cannabis packaging industry is essential for businesses looking to improve efficiency, reduce labor costs, and maintain product consistency. By investing in advanced machinery and automated processes, companies can stay competitive in this rapidly growing market and meet the evolving needs of their customers.