Flexible Packaging vs. Glass Jars: A Comprehensive Guide to Cannabis Packaging Solutions

The cannabis industry finds itself at a crossroads as it experiences exponential growth. This growth has presented manufacturers with vital decisions to make, one of which concerns product packaging. Two popular alternatives – pre-made pouch and traditional glass jars – each possesses their own set of advantages and disadvantages. In this guide, we will explore these pros and cons, discuss the benefits of automating the packaging process, and examine how LeafyPack can help you find the ideal machinery solution for your cannabis business.

| Criterion | Pre-Made Pouch | Glass Jars |

|---|---|---|

| Cost | Lower material and shipping costs | Higher material and shipping costs |

| Sustainability | Lighter weight, recyclable materials | Reusable, recyclable, but heavier |

| Design & Branding | Eye-catching, customizable designs | Limited options, but premium appeal |

| Protection & Preservation | High barrier properties | Airtight seal, UV protection |

| Usability & Features | User-friendly, child-resistant options | Timeless look, reusability |

| Durability | Perceived as less durable | Fragile, prone to breakage |

| Environmental Impact | Lower carbon footprint | Higher carbon footprint due to weight and transportation |

A Tale of Two Packages: Pre-Made Pouch and Glass Jars

As we compare pre-made pouch and glass jars, it’s important to consider criteria such as cost, sustainability, design and branding, product protection, usability, durability, and environmental impact. By weighing these factors, you can make an informed decision about the best packaging option for your cannabis products.

Pre-Made Pouch: The Smart, Sustainable Solution

Pre-made pouch has emerged as an increasingly attractive option for cannabis manufacturers. It boasts a lower material and shipping cost, lighter weight, and recyclable materials. This packaging option also allows for eye-catching, customizable designs that help your cannabis products stand out in a crowded market. High barrier properties in pre-made pouch protect your products from external factors like moisture, oxygen, and UV light, ensuring freshness and potency. Additionally, user-friendly features such as resealable pouches and child-resistant options make pre-made pouch appealing to consumers.

Glass Jars: The Classic, Premium Choice

Glass jars exude a premium appeal, elevating your cannabis brand’s image. They are reusable and recyclable, supporting sustainability efforts while providing an airtight seal to maintain product freshness, aroma, and flavor. Tinted glass jars protect your products from harmful UV light, preserving their potency over time. Despite their timeless look and elegant appeal, glass jars present challenges like higher costs, fragility, and heavier weight, which contribute to a higher carbon footprint.

The Art of Automation in Packaging

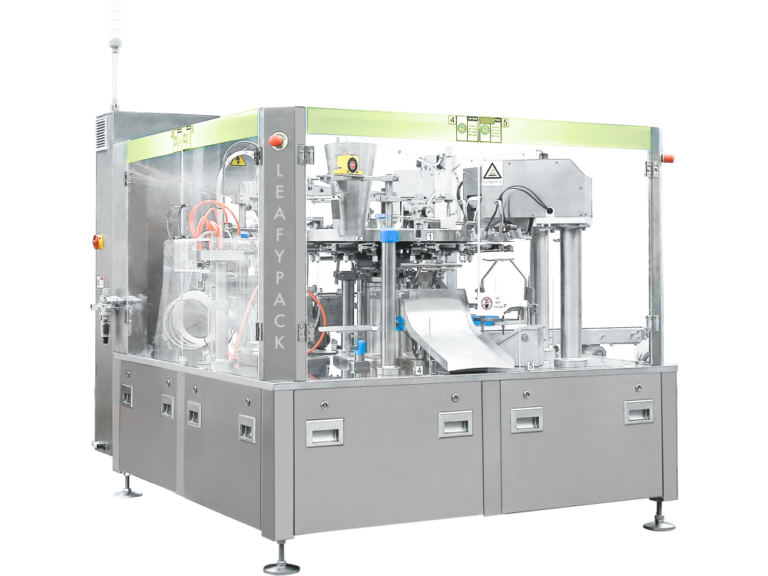

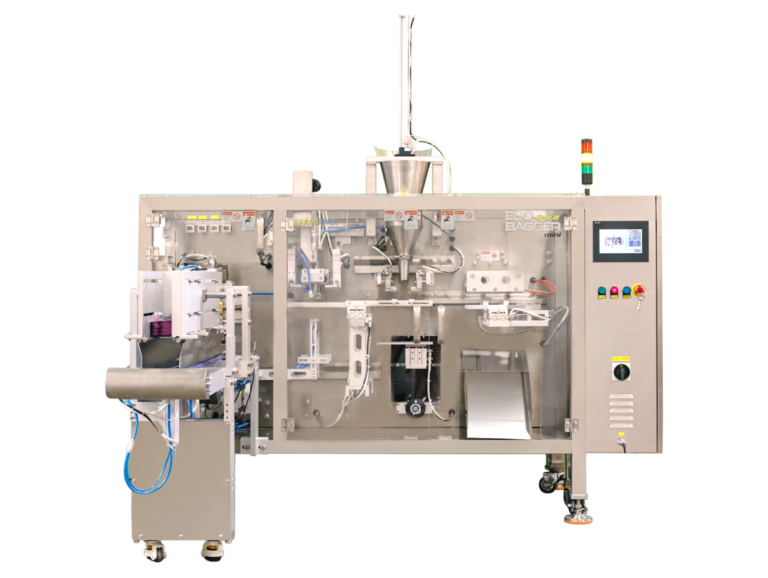

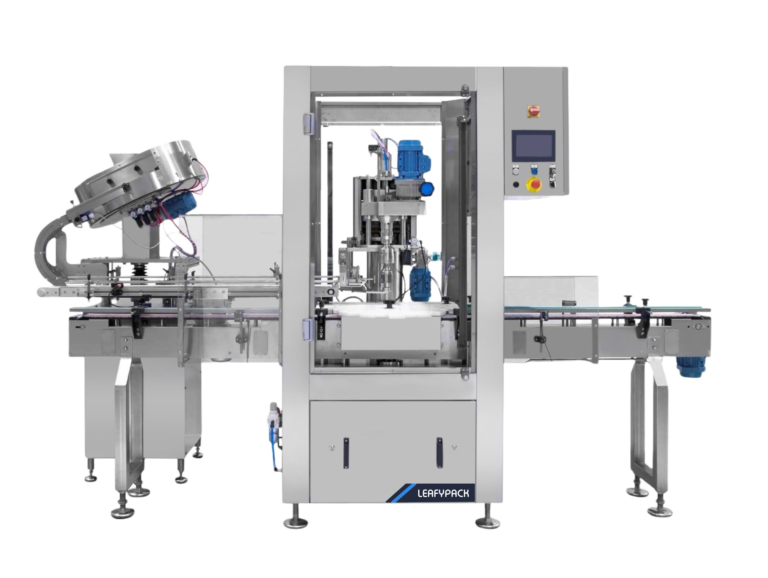

Automating the packaging process can provide significant benefits for both pre-made pouch and glass jars, including increased efficiency, reduced labor costs, improved product consistency, and enhanced quality control. LeafyPack offers a wide range of machines that can help you automate various aspects of your packaging process, such as filling, capping, labeling, and bagging.

Some of the machines available on LeafyPack include:

By investing in automated packaging solutions, you can streamline your operations, reduce errors, and maintain a competitive edge in the cannabis market.

LeafyPack: Your Catalyst for Cannabis Packaging Machinery Solutions

Selecting the right machinery for your cannabis packaging process can be overwhelming. That’s where LeafyPack enters the picture. As a leading supplier of cannabis packaging machinery, LeafyPack offers a wide range of equipment tailored to meet the unique needs of your cannabis business.

By referencing the table comparison above and considering factors such as cost, sustainability, branding, and product protection, you can make an informed decision about which packaging option is best for your cannabis products. Regardless of your choice, LeafyPack is committed to helping you find the most suitable machinery solution that meets industry regulations and exceeds consumer expectations.

To sum up, both pre-made pouch and glass jars have their merits, and the right choice depends on your specific needs and target market. By carefully weighing the pros and cons of each option and exploring the benefits of automating the packaging process with specialized machines like the RotoBagger and EcoBagger, you can ensure that your cannabis products are packaged in a way that best aligns with your brand identity and values.

For more information on packaging machinery, industry news, and other resources, visit LeafyPack’s various tools and resources available to help you make the best decision for your cannabis business. From weighing and filling to labeling and capping, LeafyPack has the equipment and expertise to assist you in selecting the perfect packaging machinery solution for your unique cannabis products. Stay up to date with the latest developments in the cannabis packaging industry by visiting the News page on LeafyPack, and explore the Trade Show Schedule to find opportunities to connect with industry professionals and discover new packaging innovations.

Conclusion

The choice between pre-made pouch and glass jars comes down to your business’s specific requirements and priorities. Each option has its advantages and drawbacks, and understanding these differences will help you make an informed decision. By leveraging automation and partnering with a trusted supplier like LeafyPack, you can optimize your cannabis packaging process and enhance your brand’s appeal to consumers.