Best Features to Look Out For in a Cannabis Multi-Head Weigher

In the rapidly growing cannabis industry, precision and efficiency are paramount. A multi-head weigher stands out as an essential tool, renowned for its accuracy, speed, and reliability. Historically, these machines were used to weigh various products, but with the rise of the cannabis sector, they’ve become crucial in ensuring precise measurements for packaging cannabis products.

A typical weigher disperses the product hoppers, then transfers it to an empty weight hopper. Automated mechanisms within these machines determine the product’s mass across the weight hoppers. This system ensures the product is weighed accurately, closest to the target weight, before being dispensed to distribution systems.

When investing in a multi-head weigher for cannabis packaging, it’s vital to select features that guarantee optimal production performance. This article dives into the essential features manufacturers should consider to boost their business’s profitability, productivity, and competitiveness.

1. Accuracy and Efficiency

For cannabis products, ensuring accurate measurements is crucial. A high-accuracy packing scale machine guarantees consistent packing targets, maximizing profitability and minimizing waste. This precision is especially vital in the cannabis industry, where slight deviations in weight can have significant implications. Efficient and accurate weighers enhance profitability and productivity, allowing businesses to meet market demands and capitalize on sales opportunities.

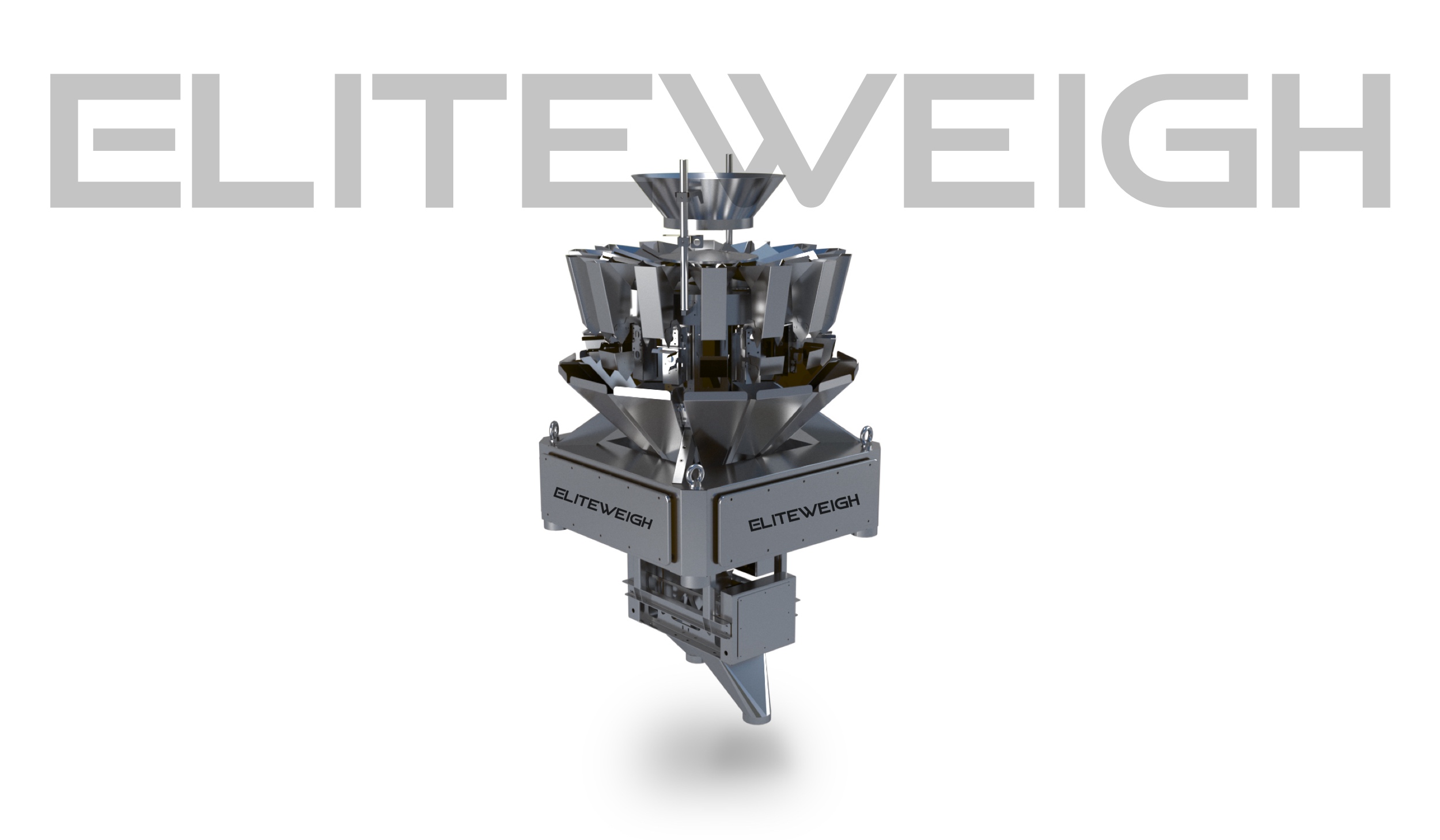

Adding to this, the EliteWeigh Multihead Weigher is NTEP Certified, which guarantees high precision and performance when it counts the most. This certification ensures that the weigher meets the highest standards for accuracy, making it a reliable choice for businesses in the cannabis industry. For more details, you can read the article about the EliteWeigh Multihead Weigher on Packworld.

2. Number of Heads

The number of heads in a multi-head weigher refers to individual weigh hoppers or weighing units. Each head consists of a load cell and a discharge mechanism. The ideal number of heads depends on various factors, including the physical properties of the cannabis products and the desired production throughput. It’s essential to balance budget considerations with accuracy needs.

3. Weighing Range

A versatile multi-head weigher should accommodate various cannabis products, from buds to edibles. It’s crucial to consider the minimum and maximum weights the products might have, ensuring the machine can handle the entire weight range. A weigher with a broad dynamic range offers flexibility for various products.

4. Hopper Capacity

Hoppers play a vital role in storing and dispensing cannabis products during the weighing process. It’s essential to consider the product’s flow characteristics and bulk density when choosing the right hopper capacity. Ensuring the hopper capacity aligns with the equipment’s power and speed is crucial for an efficient production process.

5. Maintenance and Support

Reliable technical support and maintenance are crucial for the smooth operation of a multi-head packing machine in the cannabis industry. Features like fault detection and diagnostics can help in proactive maintenance, reducing the risk of unexpected breakdowns.

In the competitive cannabis market, choosing the right equipment is essential. LeafyPack offers a comprehensive range of high-quality packaging solutions tailored for the cannabis industry. Prioritizing reliability and quality, our products are designed to meet the unique demands of this growing sector. Contact us for a free consultation and discover how you can elevate your cannabis production line with a multi-head weigher.