Automation: Boosting Efficiency and Reducing Costs

Introduction

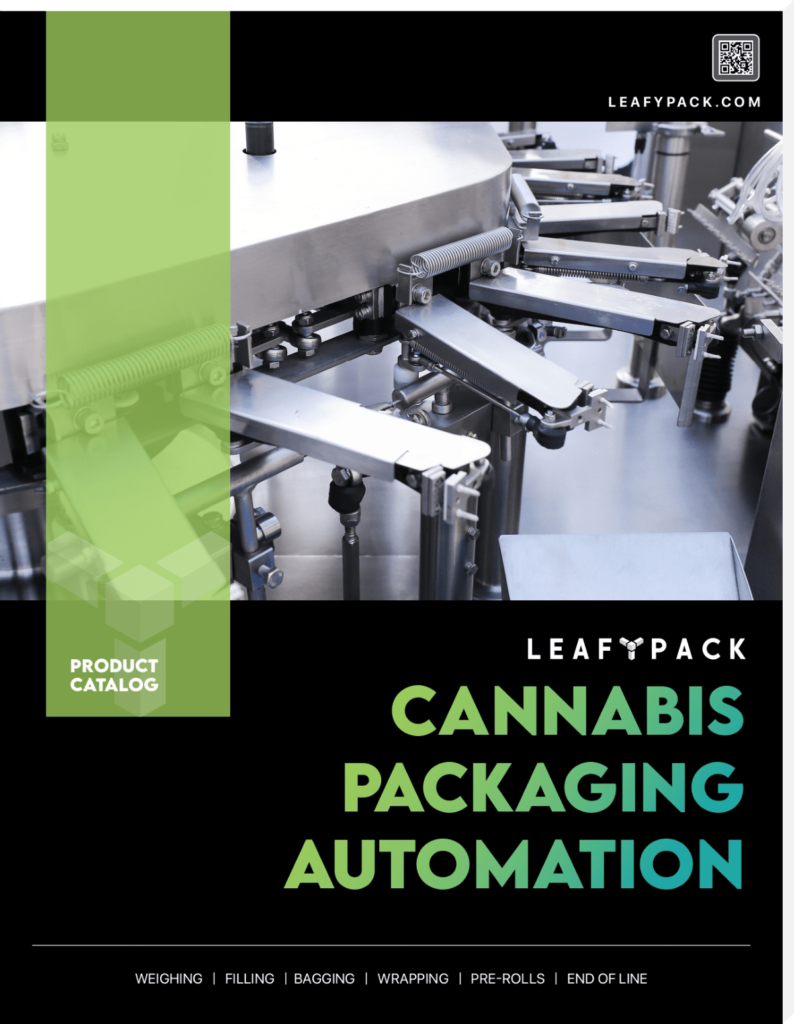

As the cannabis industry continues to grow, many businesses are turning to automation to streamline their packaging processes, reduce labor costs, and increase overall efficiency. Automated packaging equipment can help businesses save time, minimize waste, and maintain a competitive edge in a rapidly evolving market. This article will discuss the benefits of automating cannabis packaging processes and highlight some key equipment options available from LeafyPack

Benefits of Automation in Cannabis Packaging

Increased Efficiency

Automating packaging processes can significantly improve efficiency by reducing manual labor and speeding up production rates. Automated equipment can consistently package products at a faster pace than human workers, allowing businesses to meet increased demand and reduce turnaround times.

Reduced Labor Costs

Labor costs can be a significant expense for cannabis businesses, especially during periods of rapid growth. By automating packaging processes, businesses can reduce their reliance on manual labor, lower labor costs, and allocate resources more effectively.

Improved Consistency and Quality

Automated packaging equipment can help maintain consistent quality and presentation of cannabis products by minimizing human error and ensuring a uniform appearance. Consistent packaging can enhance brand image and customer satisfaction, leading to increased sales and customer loyalty.

Enhanced Scalability

Automation can make it easier for businesses to scale their operations as demand increases. Automated equipment can be easily integrated into existing production lines, allowing businesses to grow their capacity without the need for significant additional investment.

Key Automated Packaging Equipment Options from LeafyPack

The Apollo Pre-Roll Machine is a high-speed, automated solution for filling and packing pre-rolled cannabis joints. With the ability to process up to 1,200 pre-rolls per hour, this machine can significantly increase production rates and reduce labor costs associated with manual pre-roll production.

The Cannabis Multihead Weigher is designed to accurately and efficiently weigh cannabis flower, ensuring precise portion control and minimizing product waste. By automating the weighing process, businesses can improve efficiency and maintain consistent product quality.

Automatic Capping Machine with Lid Feeder

This automatic capping machine is designed to quickly and accurately apply caps to cannabis containers, ensuring a secure and tamper-evident seal. By automating the capping process, businesses can reduce labor costs and improve overall efficiency.

Automated liquid concentrate filling machines can streamline the packaging process for cannabis tinctures, vape cartridges, and other liquid products. By automating the filling process, businesses can ensure consistent product quality and reduce the risk of spills and waste.

Conclusion

Automation in cannabis packaging offers numerous benefits, including increased efficiency, reduced labor costs, and improved product consistency. By investing in automated equipment from reputable suppliers like LeafyPack, cannabis businesses can stay competitive in a rapidly evolving market and better position themselves for future growth.